Cummins ISX Oil Pressure Sensor Location

If you’re having maintenance issues, especially if your dashboard is showing its check engine lights, the oil light is flashing, or the oil display is showing an inaccurate reading, you may need a new oil pressure sensor.

The Cummins ISX oil pressure sensor is an integral part of a Cummins ISX engine. It’s responsible for sending an accurate oil pressure reading to the vehicle’s computer.

The Cummins ISX oil pressure sensor location has been a struggle point for many mechanics, but luckily in this guide, we will explain exactly where it is located and how to replace a faulty one.

What Is the Cummins ISX Oil Pressure Sensor

The oil pressure sensor is an important component of any diesel engine, as it helps to regulate the pressure of the oil flowing through the system. This allows the vehicle’s computer to determine when to adjust the engine’s performance, such as when to add fuel or spark to increase or decrease power.

Cummins ISX Oil Pressure Sensor Location

These sensors can be difficult to locate , and if you’re experiencing issues or need to do an annual check-up, you’ll need to find it immediately.

The Cummins ISX oil pressure sensor is located on the rear of the engine, inside the transmission case. It's easy to locate because it's behind the fuel filter and ECM. The sensor is typically connected to the engine block with two bolts.

When replacing the oil pressure sensor, it’s important to use the correct type and size for your engine model. The wrong type of sensor can cause inaccurate readings and can cause damage to the engine.

Symptoms Of Faulty Sensors

When the oil pressure sensor fails, it can cause the engine to run poorly. Some of the most common symptoms of a faulty oil pressure sensor include the following:

In addition, if the oil pressure light is on or blinking or the oil pressure gauge is showing zero, the oil pressure sensor may fail.

Oil pressure sensors usually degrade throughout their life cycle. As the sensor ages, it becomes less reliable at accurately detecting the oil pressure. If your oil pressure sensor is not working correctly, it could be because it has become blocked by debris, has excessive wear and tear, or has simply seen the end of its life cycle.

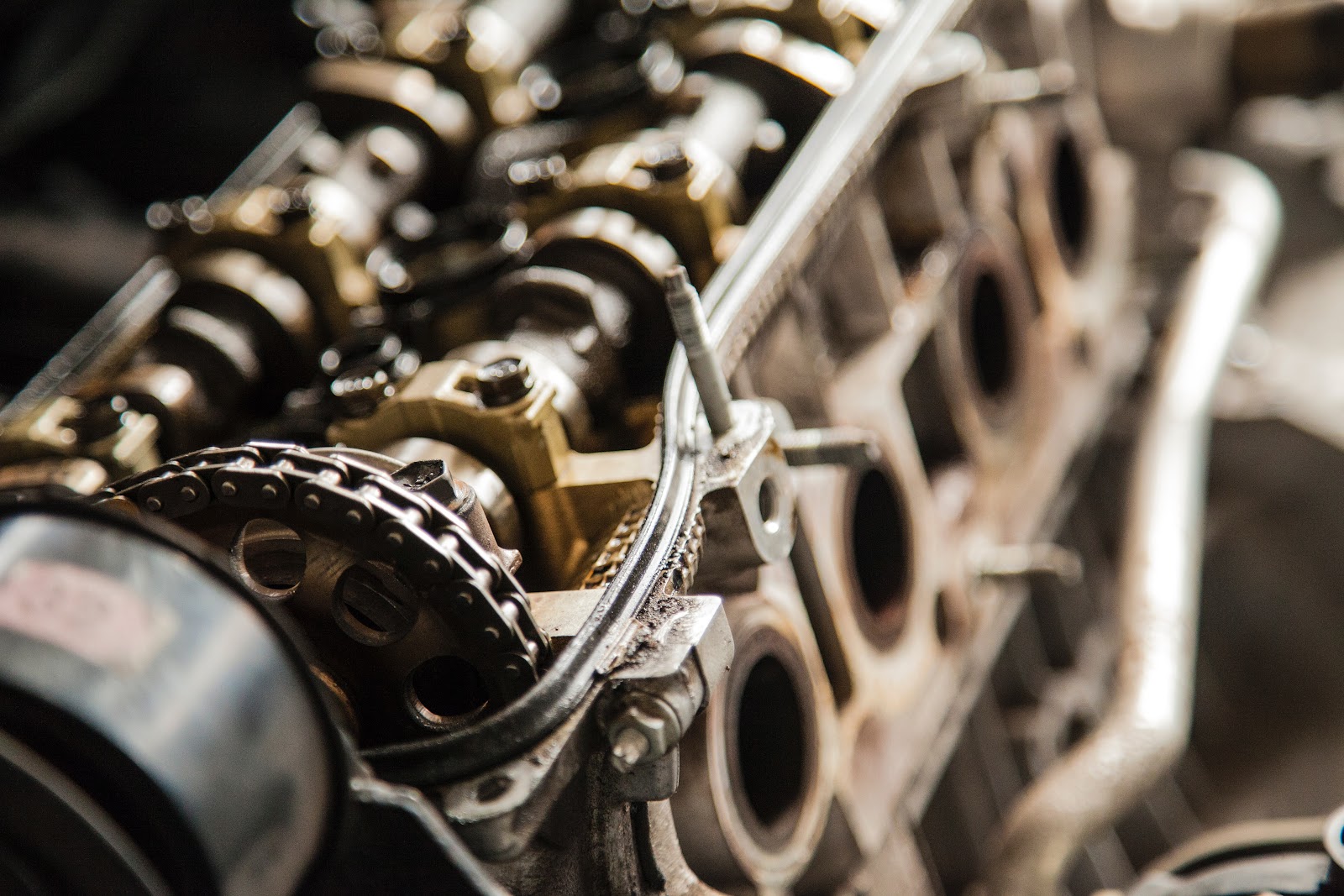

What Does An Oil Pressure Sensor Look Like

A Cummins ISX oil pressure sensor looks like a round metal cylinder with two wires coming out of it. Its exterior is black and will have a red clip that sticks into it. The wires are attached to the engine control module (ECM) or other components that monitor the oil pressure.

How do I replace my oil pressure sensor?

These are the quick steps to replace a faulty oil pressure sensor so that the fault code can disappear and you can operate the vehicle safely:

Gather Materials

You will need a 1/16" deep socket, a universal wobble joint, and a 3⁄8" adapter wrench.

Remove the Sensor

The sensor contains a red clip that holds it in place, which you need to unlock first before removing the sensor. Slide the red clip sideways to unfasten it.

Insert your 1/16 deep socket onto the pressure sensor. When placing the socket over the sensor, be careful not to damage it. Attach your adapter ratchet to your deep socket. Then, link the universal wobble joint to the adapter ratchet.

Carefully loosen the socket, which will remove the sensor.

Clean the Connector

If any oil leaks are coming from the connection point, use an electronic cleaning tool to clean them up. Then wipe them off with a cloth.

Connect the New Sensor

-

Put the sensor together with its extension. Attach the ratchet at the end of the extension.

-

Slowly tighten the sensor until it feels tight but be careful not to overtighten.

-

The sensor contains a rubber gasket, so you do not need thread tape.

-

Slide the red clip again sideways to lock it. You may hear a click when it is completely locked.

Test the Engine

Start the engine and let the ECM check the oil pressure for a few moments. Continue to let the engine run for a few minutes, giving the ECM time to adjust to the new sensor.

If the oil pressure gauge shows a reading, all the check valves are open, and the engine runs smoothly, the sensor has been installed successfully.

Replacement Cost Of Sensor

If you're going to change the sensors, then changing them yourself is usually cheaper than having a mechanic replace them. With the help of this guide, you should be able to do this for yourself.

When purchasing, check your engine model and size to ensure you purchase the right product. Always use a trusted website like Heavy Duty Pros to purchase your parts.

Frequently Asked Questions:

How to Check The Oil Level In the Equipment?

There are many ways to check the oil level. One way is to look inside the oil filler cap. Another way is to measure the oil level using the dipstick in the oil tank.

Should I Drain the Oil For Sensor Replacement?

You don't have to drain the oil when changing the sensors.

What is Engine Oil Pressure?

It usually ranges from 25 to 65 psi. This depends on the make, model, and size of your equipment.

Should I Change My Oil Pressure Sensor Every Year?

Oil pressure sensors get old after about five years. They also wear down faster if they are exposed to extreme temperatures.

Find Your Engine Sensor At Heavy Duty Pros

A properly functioning oil pressure sensor is very important for your equipment's safe and efficient operation. With a malfunctioning sensor, it’s possible to put your engine at unnecessary risk.

Now that you know the Cummins ISX oil pressure sensor location and how to install it, check out Heavy Duty Pros for all your sensor needs. Be sure to visit the website if you’re looking for information on the quality Cummins parts, or our large inventory of other heavy duty brands.